Call: 08071793176

Paper Calender Machines

Price 260000.0 INR/ Unit

MOQ : 1 Unit

Paper Calender Machines Specification

- Grade

- Semi-Automatic

- Type

- Other

- Material

- Mild Steel / Cast Iron

- Capacity

- 500 - 3000 Kg/Shift

- Computerized

- Yes

- Control System

- Other

- Cutting Speed

- 30 - 120 m/min

- Cutting Size

- Up to 2600 mm

- Cutting Thickness

- 0.05 0.8 mm

- Voltage

- 220-380 V

- Power

- 7.5 - 15 kW

- Weight (kg)

- 2200 - 4500 kg

- Dimension (L*W*H)

- 4200 x 1700 x 1900 mm

- Color

- Blue & White

Paper Calender Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Jaipur

- Payment Terms

- Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About Paper Calender Machines

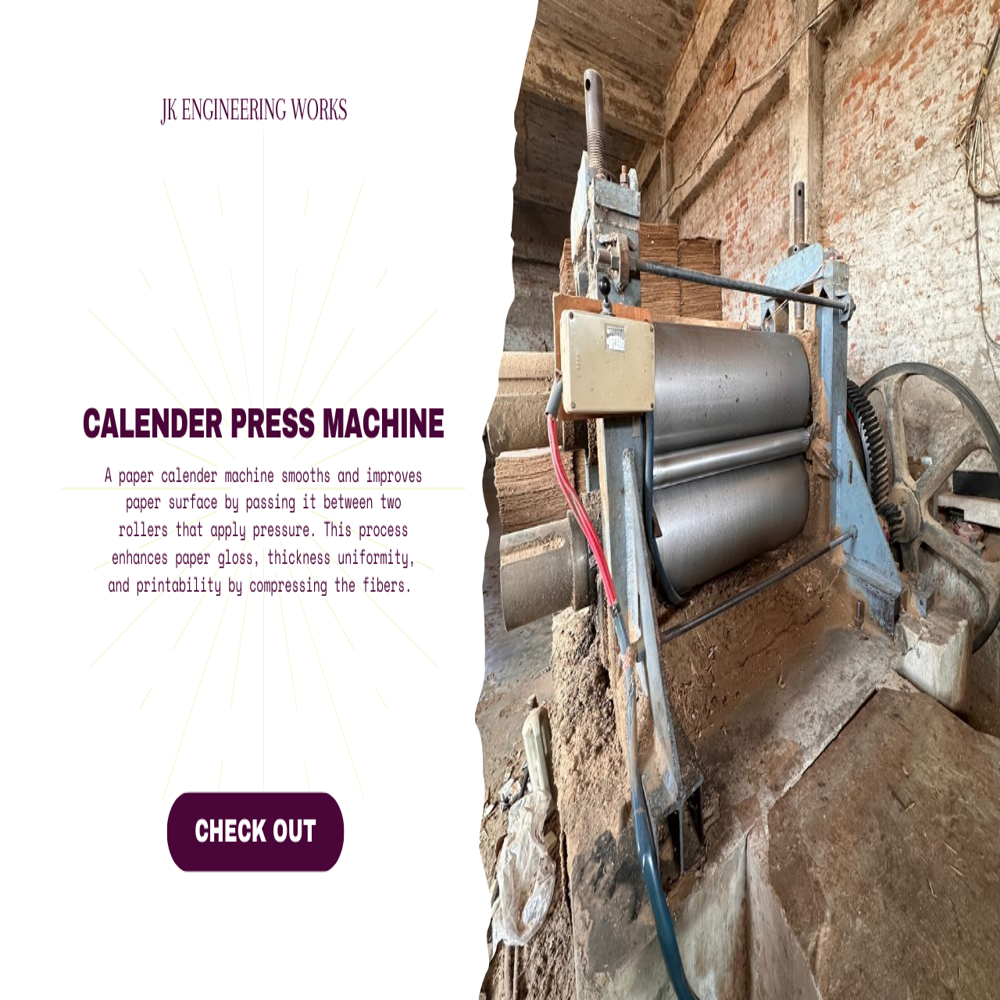

Take advantage of unrivaled technology with our Automatic Paper Calender Machinesengineered as a noble masterpiece for paper finishing excellence. Equipped with chrome plated or hard rubber rollers (3, 5, or 7 optional), this fully automatic marvel delivers mirror or glossy surfaces, reducing paper thickness efficiently. Benefit from options like electric or oil heating, a noise level below 65 dB, and an intelligent PLC touch screen. Try Now! Get It Now for superior glossing and smoothing at up to 120 m/min with safe, automated operation. Installation services available. Exporter, manufacturer, and supplierIndia.

Versatile Usage and Refined Features

Our Paper Calender Machines are ideal for industrial applications, offering precise paper glossing, smoothing, and thickness reduction. The machines automatic sheet feeder, computerized PLC/touch screen control, and variable roller configuration provide flexibility and efficiency in usage. Designed for high-capacity operations, it ensures consistent surface finish and dependable performance, making it perfect for manufacturers seeking superior-quality paper processing. Safety features like emergency stops and guards assure secure and worry-free production.

Payment, Export Markets, and Sample Policies

Our Paper Calender Machines are available with flexible payment terms, ensuring smooth expenditure management for clients. We cater extensively to international markets, proudly exporting to diverse regions from India. Packing & Dispatch are handled with utmost care to maintain machine integrity. Sample policies are transparent, and list price details are provided upon request, enhancing business trust. Clients enjoy a streamlined purchasing experience, from initial quotation to final shipment.

Versatile Usage and Refined Features

Our Paper Calender Machines are ideal for industrial applications, offering precise paper glossing, smoothing, and thickness reduction. The machines automatic sheet feeder, computerized PLC/touch screen control, and variable roller configuration provide flexibility and efficiency in usage. Designed for high-capacity operations, it ensures consistent surface finish and dependable performance, making it perfect for manufacturers seeking superior-quality paper processing. Safety features like emergency stops and guards assure secure and worry-free production.

Payment, Export Markets, and Sample Policies

Our Paper Calender Machines are available with flexible payment terms, ensuring smooth expenditure management for clients. We cater extensively to international markets, proudly exporting to diverse regions from India. Packing & Dispatch are handled with utmost care to maintain machine integrity. Sample policies are transparent, and list price details are provided upon request, enhancing business trust. Clients enjoy a streamlined purchasing experience, from initial quotation to final shipment.

FAQs of Paper Calender Machines:

Q: How does the automatic feeding system in your Paper Calender Machines work?

A: The auto sheet feeder is designed to streamline the process by automatically guiding sheets into the machine, reducing manual labor and increasing operational efficiency. It ensures consistent feeding rates, which results in uniform calendering quality throughout production.Q: What specific applications can these Paper Calender Machines be used for?

A: These machines are ideally used in industrial paper glossing, smoothing, and thickness reduction applications. They are suitable for manufacturers requiring high-quality finishes and precise thickness control for various paper products.Q: Where do you export your Paper Calender Machines?

A: We proudly supply our Paper Calender Machines to global markets, with a primary export base in India and shipments dispatched to several international destinations as per client requirements.Q: What safety features are integrated into the machines?

A: Each unit includes safety guards and an emergency stop feature, ensuring operators can halt the machine instantly in case of an emergency. This enhances operator safety during all operational phases.Q: What is the recommended process for installation and after-sales support?

A: We offer comprehensive installation services through skilled technicians. Post-installation, we provide maintenance guidance and responsive after-sales support to ensure your machines optimal performance.Q: What are the benefits of choosing a fully automatic, computerized calender machine?

A: Choosing a fully automatic, computerized model brings benefits such as increased production speed, precise control of operation parameters through a touch screen PLC, reduced manpower requirements, and enhanced product consistency, ultimately reducing production costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Machine Category

Mill board Machine

Price 1090000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Grade : SemiAutomatic

Material : Mild Steel

Dimension (L*W*H) : 3500 x 1900 x 2200 mm Millimeter (mm)

Paper Board Machine

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Grade : SemiAutomatic

Material : Steel

Dimension (L*W*H) : Tailored as per requirements Foot (ft)

Hollander Beater Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Frequency Speed Control

Grade : SemiAutomatic

Material : Steel

Dimension (L*W*H) : Customize

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry