Call: 08071793176

Mill board Machine

Price 1090000.0 INR/ Unit

MOQ : 1 Unit

Mill board Machine Specification

- Grade

- Semi-Automatic

- Type

- Other

- Material

- Mild Steel

- Capacity

- 1500-2000 sheets per shift Pcs/hr

- Computerized

- No

- Control System

- PLC Control

- Cutting Speed

- 25-40 cuts per minute km/m

- Cutting Size

- Up to 1000 x 1200 mm

- Cutting Thickness

- 2-25 mm Millimeter (mm)

- Voltage

- 380 V Volt (v)

- Power

- 7.5 kW Watt (w)

- Weight (kg)

- 3200 kg Kilograms (kg)

- Dimension (L*W*H)

- 3500 x 1900 x 2200 mm Millimeter (mm)

- Color

- Blue & White

Mill board Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Jaipur

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Mill board Machine

Explore the opulence of next-level industrial machinery with our Elite Mill Board Machine. Designed for both manual and automatic feeding, this extraordinary equipment features a high-carbon steel blade and a durable powder-coated finish. Experience rare efficiency with computerized PLC control and a powerful 7.5 kW electric drive, delivering an impressive capacity of 1500-2000 sheets per shift. Safety is paramount with the integrated emergency stop and interlock systems. Pick yours today and elevate your production process with minimized noise and readily available installation and spare support.

Versatile Mill Board Machine: Precision and Performance

The Mill Board Machine is designed for precise cutting and forming of mill boards up to 1000 x 1200 mm and thicknesses from 2-25 mm. Its versatility makes it ideal for a range of industrial applications, from insulation board manufacturing to specialty packaging. The machines PLC control ensures smooth operation, while its superior build provides stability, safety, and high efficiency, giving users a competitive advantage in streamlined production environments.

Global Supply, Seamless Delivery & Competitive Offers

As a leading exporter, manufacturer, and supplier from India, we offer the Mill Board Machine to an elite global clientele. Our packing & dispatch standards ensure secure transit through major FOB ports, supporting swift international delivery. Boasting extensive supply ability, we meet high-volume demands at a competitive sale price, delivering genuine value. Each shipment includes full documentation and after-sales support, providing assurance for our worldwide customers.

Versatile Mill Board Machine: Precision and Performance

The Mill Board Machine is designed for precise cutting and forming of mill boards up to 1000 x 1200 mm and thicknesses from 2-25 mm. Its versatility makes it ideal for a range of industrial applications, from insulation board manufacturing to specialty packaging. The machines PLC control ensures smooth operation, while its superior build provides stability, safety, and high efficiency, giving users a competitive advantage in streamlined production environments.

Global Supply, Seamless Delivery & Competitive Offers

As a leading exporter, manufacturer, and supplier from India, we offer the Mill Board Machine to an elite global clientele. Our packing & dispatch standards ensure secure transit through major FOB ports, supporting swift international delivery. Boasting extensive supply ability, we meet high-volume demands at a competitive sale price, delivering genuine value. Each shipment includes full documentation and after-sales support, providing assurance for our worldwide customers.

FAQs of Mill board Machine:

Q: How does the Mill Board Machine enhance safety during operation?

A: The machine is equipped with emergency stop and interlock systems, ensuring immediate shutdown in case of any safety breach, and greatly minimizing operator risk during operation.Q: What types of mill board materials can this machine process?

A: This machine accommodates a range of mill board thicknesses (2-25 mm) and sizes (up to 1000 x 1200 mm), making it applicable to a wide variety of industrial-grade mill board types.Q: Where is installation service for the Mill Board Machine available?

A: Professional installation services are available at customer sites globally, ensuring correct setup regardless of location.Q: What is the typical process for ordering and receiving spare parts?

A: Spare parts are readily available for fast dispatch. Customers can contact our support team for swift delivery, ensuring minimal downtime in operations.Q: What are the primary benefits of using this Mill Board Machine in production?

A: Users benefit from high cutting speed (25-40 cuts per minute), robust build, computer-controlled precision, and excellent reliability, resulting in higher efficiency and consistent product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Machine Category

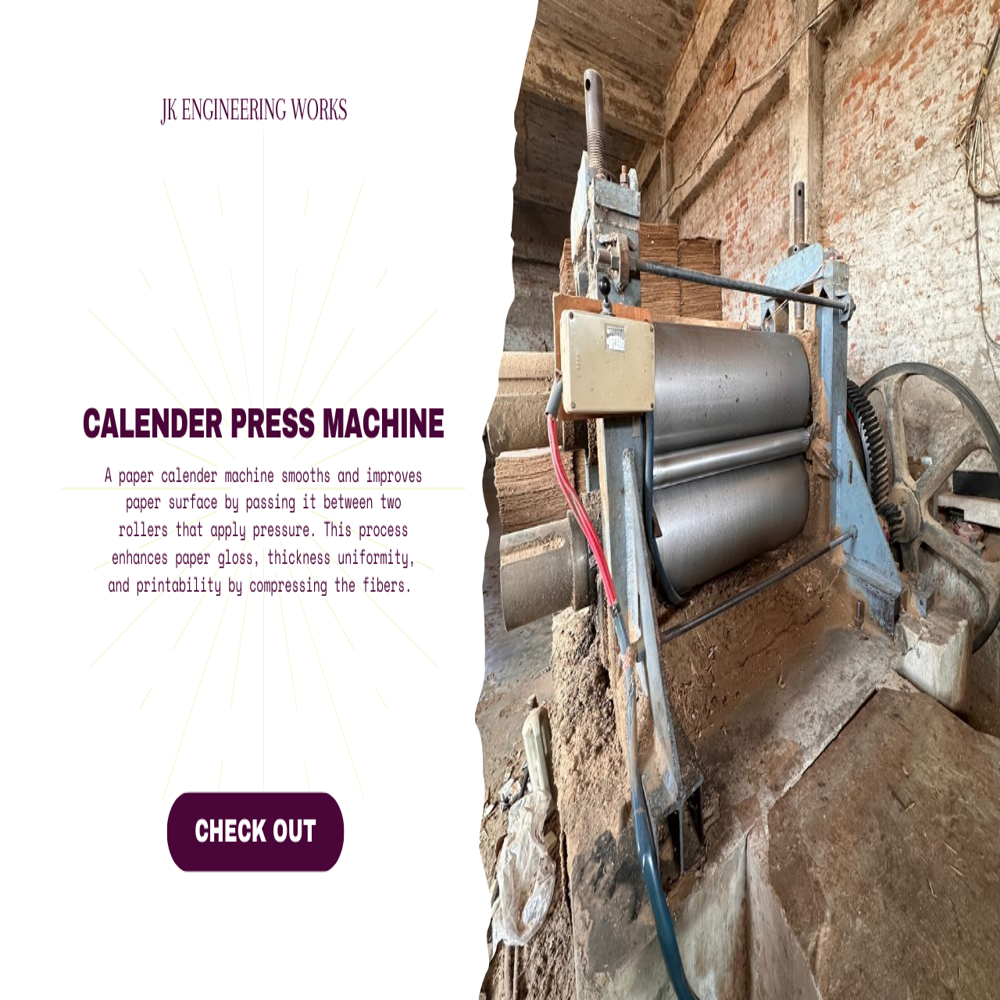

Paper Calender Machines

Price 260000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other

Computerized : Yes

Color : Blue & White

Type : Other

Paper Board Machine

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Gray

Type : Other

Hollander Beater Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Frequency Speed Control

Computerized : No

Color : Blue

Type : Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry